The International Space Station: A Systems Engineering Marvel at the Crossroads of History

Picture this: you’re managing the most complex engineering project humanity has ever attempted to keep operational 400 kilometers above Earth. Every day, you’re orchestrating systems that would make a nuclear power plant look simple, while your “office” screams around the planet at 28,000 kilometers per hour.

Welcome to the International Space Station (ISS), where systems engineering meets the ultimate stress test.

I’ve spent the last decade watching space systems evolve from my perspective in the defense sector, and nothing quite compares to the engineering marvel that is the ISS. However, as we approach 2025, this orbital laboratory stands at a fascinating crossroads. The station that once represented humanity’s greatest collaborative achievement now faces critical decisions about its future, driven by aging infrastructure and evolving space policy.

What Is the International Space Station? The Ultimate Systems Integration Challenge

The International Space Station represents the pinnacle of space systems engineering, a modular orbital laboratory that has redefined what’s possible when nations collaborate on complex technical challenges. At its core, the ISS functions as a self-sustaining ecosystem in the harsh vacuum of space, supporting human life while conducting cutting-edge research.

But here’s where it gets interesting from a systems perspective: the ISS isn’t just one system. It’s a collection of interconnected space modules that must work in perfect harmony. Think of it as the ultimate integration challenge, where failure isn’t just inconvenient, it’s potentially catastrophic.

The station operates as a microgravity research platform, enabling experiments impossible on Earth. From protein crystallization to materials science, the unique environment allows researchers to study phenomena without gravity’s interference. Moreover, the ISS serves as a proving ground for space technology that will eventually enable deeper space exploration.

What makes the ISS truly remarkable is its role as humanity’s first permanent foothold in space. Unlike previous space stations that were national projects, the ISS demonstrates how complex systems can be built through international cooperation, a lesson that’s invaluable for future space endeavors.

The Multinational Engineering Partnership: Who Operates the ISS?

The ISS operates under one of the most complex international partnerships in engineering history. Five major space agencies collaborate to keep this orbital laboratory functioning: NASA (United States), Roscosmos (Russia), ESA (European Space Agency), JAXA (Japan), and CSA (Canada).

Each partner brings unique capabilities and modules to the station. NASA provides the primary structural framework and life support systems, while Roscosmos contributes propulsion and transportation through their Soyuz and Progress vehicles. ESA delivers the Columbus laboratory and automated transfer vehicles, Japan contributes the Kibo laboratory module, and Canada provides the robotic arm systems.

This partnership model creates fascinating systems engineering challenges. Different countries use different standards, testing protocols, and design philosophies. Imagine trying to integrate Russian life support systems with American power management while ensuring Japanese experiments can operate safely alongside European research facilities.

The operational complexity extends to crew management too. Currently, crews typically include members from multiple nations, each trained on different systems and procedures. This redundancy actually enhances safety, if one crew member becomes incapacitated, others can operate critical systems.

AX-2 Cew

Physical Specifications: Engineering by the Numbers

From a systems engineering perspective, the ISS specifications are mind-boggling. The station masses approximately 450,000 kilograms, roughly equivalent to 330 automobiles floating in space. Its dimensions span 109 meters in length, 73 meters in width, and 20 meters in height, making it larger than a football field.

But size isn’t everything. The ISS travels at an average speed of 28,000 kilometers per hour, completing one orbit around Earth every 90 minutes. This orbital velocity creates unique engineering challenges, everything from thermal cycling to debris impact risks must be carefully managed.

The station maintains an altitude between 400-420 kilometers above Earth’s surface. This altitude represents a careful balance: high enough to minimize atmospheric drag (which would require frequent reboosts), yet low enough to enable relatively efficient crew and cargo transportation.

Here’s a breakdown of key specifications:

| Parameter | Value | Engineering Significance |

|---|---|---|

| Mass | 450,000 kg | Requires careful thruster management for orbital adjustments |

| Length | 109 m | Largest structure ever assembled in space |

| Width | 73 m | Creates significant moment arms for attitude control |

| Orbital Speed | 28,000 km/h | Extreme thermal and structural cycling |

| Altitude | 408 km (average) | Optimal balance of drag and accessibility |

| Crew Capacity | 6-7 astronauts | Maximum sustainable with current life support |

International Collaboration: 15 Countries, One Vision

The ISS partnership extends beyond the five primary space agencies. In total, 15 countries contribute to ISS operations, research, or crew training. This includes nations like Brazil, which participates through research partnerships, and various European countries that contribute through ESA.

From a systems engineering standpoint, this international cooperation creates both opportunities and challenges. On one hand, it provides redundancy and diverse expertise. If one country faces technical difficulties, others can provide backup systems or alternative solutions.

However, coordinating across different time zones, languages, and technical standards requires sophisticated project management. The ISS program uses standardized interfaces and communication protocols, but cultural differences in engineering approaches still surface.

Consider the different approaches to risk management. Russian systems tend to emphasize robust, field-proven technologies, while American systems often push technological boundaries. European systems focus on precision and efficiency. Japanese systems emphasize reliability and miniaturization. Integrating these philosophies requires careful systems engineering.

Construction Timeline: Building in the Ultimate Hostile Environment

The ISS construction represents one of the most complex assembly projects ever attempted. Construction began in 1998 with the launch of the Russian Zarya module, followed by the American Unity module later that year. The assembly process took over 13 years, involving more than 40 assembly flights.

Building the ISS required unprecedented coordination between space agencies. Each module had to be designed not just for its intended function, but for the complex process of orbital assembly. Modules needed to survive launch, operate independently during transit, and integrate seamlessly with existing station systems.

The construction timeline reveals the iterative nature of complex systems development:

Phase 1 (1998-2000): Core modules and basic life support Phase 2 (2000-2005): Laboratory modules and enhanced capabilities

Phase 3 (2005-2011): Final assembly and full operational capacity Phase 4 (2011-present): Continuous upgrades and maintenance

Each phase required different engineering approaches. Early phases focused on basic functionality and crew safety. Later phases added scientific capabilities and redundancy. The current phase emphasizes maintenance and preparation for eventual decommissioning.

Current Crew Operations: Life in a Complex System

As of 2025, the ISS typically hosts 6-7 crew members as part of Expedition 73, which began in April 2025. Crew rotations occur approximately every six months, though some astronauts may stay longer depending on mission requirements and transportation availability.

Living and working on the ISS requires constant interaction with complex systems. Astronauts don’t just conduct experiments, they’re also the primary maintenance crew for a machine that operates 24/7 in one of the most hostile environments imaginable.

Daily operations involve monitoring hundreds of systems parameters, from life support efficiency to solar array performance. Crew members must be skilled in everything from basic plumbing to advanced electronics repair. When something breaks on the ISS, you can’t call a repair service, you have to fix it yourself with the tools and spare parts available on station.

The crew schedule balances scientific research with maintenance tasks. Typically, astronauts spend about 35 hours per week on research activities, but this can vary significantly based on station needs. Emergency repairs always take priority over research.

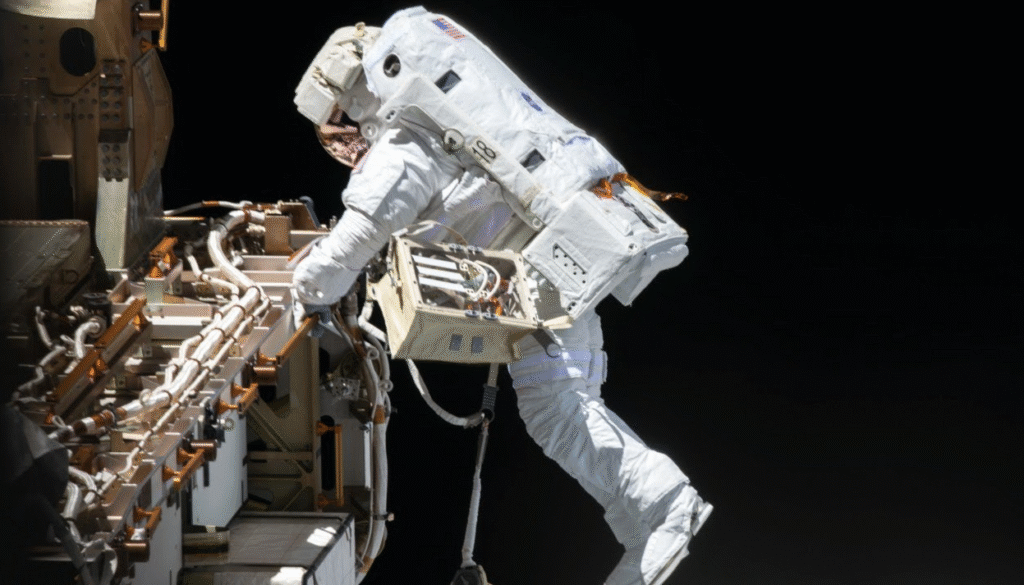

S pace

Space walk maintenance

Mission Duration: Balancing Human Factors and System Reliability

Standard ISS missions last approximately six months, though this duration reflects careful optimization of multiple factors. From a human factors perspective, six months represents a reasonable balance between crew psychological health and mission effectiveness.

However, systems engineering considerations also drive mission duration. Crew vehicles like the Soyuz and Dragon have limited on-orbit lifetimes due to component degradation in the space environment. The Soyuz spacecraft, for instance, has a maximum on-orbit duration of about 210 days before its systems begin to degrade significantly.

Some missions extend beyond six months for specific research objectives or when transportation delays occur. The longest single ISS mission was 340 days, conducted as part of research into the effects of extended spaceflight on human physiology.

Mission duration affects everything from life support consumables to crew exercise requirements. Longer missions require more supplies but provide continuity for long-term experiments. Shorter missions reduce logistical complexity but increase crew rotation overhead.

Research Capabilities: The Science Behind the Engineering

The ISS serves as humanity’s premier microgravity research platform, enabling investigations impossible on Earth. The station’s unique environment allows researchers to study phenomena without gravity’s interference, leading to breakthroughs in materials science, biology, and physics.

Research on the ISS falls into several categories:

Materials Science: Microgravity enables the creation of alloys and crystals with properties impossible to achieve on Earth. Without gravity-driven convection, materials can form more uniform structures, potentially revolutionizing manufacturing.

Biological Research: Scientists study how living systems adapt to microgravity, providing insights into fundamental biological processes. This research has implications for both space exploration and Earth-based medical treatments.

Physics Research: The ISS enables studies of combustion, fluid dynamics, and particle physics in ways impossible on Earth. These experiments often reveal new fundamental principles.

Technology Demonstration: The station serves as a testbed for space technology that will enable future deep space missions. From life support systems to materials handling, the ISS proves concepts before they’re used on Moon or Mars missions.

Recent research has led to advances in drug development, with several medications now in clinical trials based on ISS research. The station has also enabled the development of new alloys and manufacturing techniques that are finding applications in Earth-based industries.

Alex Gerst; Courtesy of NASA

Architectural Overview: Form Following Function in Space

The ISS architecture reflects the unique challenges of space-based systems design. The station’s distinctive shape, with its large solar arrays and modular construction, isn’t just aesthetic; it’s the result of careful engineering optimization.

The station’s backbone consists of the truss structure, which provides mounting points for solar arrays, radiators, and other external equipment. This truss also houses the primary power and data distribution systems. The pressurized modules attach to this truss, creating the living and working spaces for crew members.

When viewed from Earth, the ISS appears as a bright star moving across the sky. Its distinctive shape is visible through telescopes, showing the T-shaped configuration of the main truss with solar arrays extending like wings. The various modules create the “body” of the station, housing laboratories, living quarters, and life support systems.

The station’s orientation is carefully controlled to optimize solar power generation while maintaining communication with Earth. The solar arrays are continuously adjusted to track the sun, while the station’s attitude is managed to present the proper antennas toward Earth for communication.

Module Configuration: The Building Blocks of Space Living

The ISS consists of multiple interconnected space modules, each designed for specific functions. As of June 2025, nasa.gov states that there are 43 different modules and elements installed on the ISS. This modular approach provides flexibility and redundancy while enabling incremental assembly.

Pressurized Modules:

- Zarya: The first module, providing initial power and propulsion

- Unity: The connecting node that links Russian and American segments

- Destiny: The primary US laboratory module

- Columbus: The European laboratory module

- Kibo: The Japanese experiment module, the largest single ISS module

- Tranquility: Contains life support systems and the famous cupola observation deck

Unpressurized Elements:

- Truss Structure: The backbone providing power and thermal management

- Solar Arrays: Eight arrays generating over 120 kilowatts of power

- Radiators: Thermal management systems essential for heat rejection

- Docking Ports: Multiple ports for visiting vehicles and crew transportation

Each module represents a significant engineering achievement. They must survive launch loads, operate independently during assembly, and integrate seamlessly with existing station systems. The modular design enables upgrades and replacements, extending the station’s operational life.

Daily Operations: Systems Engineering in Action

Living and working on the ISS requires constant interaction with complex systems. Astronauts serve multiple roles: they’re researchers, maintenance technicians, and system operators all rolled into one.

A typical day begins with a Daily Planning Conference (DPC) where crew members coordinate with mission control centers around the world. This conference reviews the day’s activities, addresses any system anomalies, and ensures everyone understands priorities.

The crew then disperses to their assigned tasks. Some may conduct scientific experiments while others perform maintenance on life support systems. The station requires constant upkeep, from changing air filters to replacing failed electronics.

Exercise is a critical part of daily operations. In microgravity, muscle and bone mass deteriorate rapidly without countermeasures. Crew members spend 2.5 hours daily on specialized exercise equipment, which itself requires regular maintenance.

Emergency procedures are always at the forefront of operations. Crew members train extensively for scenarios like fires, rapid depressurization, or toxic atmosphere events. The station’s design includes multiple escape routes and emergency equipment.

Power Systems: Engineering Reliable Energy in Space

The ISS power system represents one of the most complex electrical systems ever deployed in space. Eight solar arrays generate over 120 kilowatts of power, enough to power about 55 homes on Earth. However, the space environment creates unique challenges for power generation and distribution.

Solar arrays must constantly track the sun while the station orbits Earth every 90 minutes. This means the arrays rotate continuously, requiring sophisticated control systems and rotary joints. The arrays also face extreme temperature variations, from -157°C in shadow to +121°C in sunlight.

Power distribution involves multiple voltage levels and redundant pathways. The primary power system operates at 160 volts DC, which is then converted to various voltages for different systems. Critical systems have multiple backup power sources, ensuring crew safety even if primary systems fail.

Battery systems provide power when the station passes through Earth’s shadow. These batteries must charge and discharge up to 16 times per day, creating significant thermal and electrical stress. The station has undergone multiple battery upgrades as technology has improved.

Power management becomes particularly complex during solar array installations or repairs. Mission controllers must carefully balance power loads, sometimes shutting down non-essential systems to maintain adequate power margins.

Visibility from Earth: A Moving Testament to Engineering

One of the most remarkable aspects of the ISS is its visibility from Earth. The station appears as a bright, fast-moving star, crossing the sky in about 6 minutes. This visibility isn’t accidental, it’s the result of the station’s large size and reflective surfaces.

The ISS is the third-brightest object in the night sky after the Moon and Venus. Its brightness varies depending on the angle of the solar arrays relative to the observer and the station’s altitude. During optimal conditions, the ISS can be as bright as magnitude -6, making it easily visible even in urban areas with light pollution.

For engineers, the station’s visibility provides a constant reminder of what’s possible when complex systems work together. Every time you see the ISS pass overhead, you’re witnessing the successful operation of thousands of interconnected systems, all working in perfect harmony 400 kilometers above Earth.

The visibility also serves practical purposes. Ground-based observers can verify the station’s position and attitude, providing additional data for mission controllers. Amateur astronomers have even captured detailed images of the ISS, sometimes revealing information about the station’s configuration or orientation.

Structural Integrity: The Aging Infrastructure Challenge

As we progress through 2025, the ISS faces increasing challenges related to its aging infrastructure. The panel pointed to ongoing structural problems in the Zvezda module, specifically cracks in the PrK vestibule—a key junction in the Russian segment. These cracks, which have eluded a definitive cause or solution, are being closely monitored by both NASA and Roscosmos.

The aging process affects multiple systems simultaneously. Mechanical components experience fatigue from constant thermal cycling and micro-meteoroid impacts. Electronic systems face degradation from radiation exposure and thermal stress. Life support systems require increasingly frequent maintenance as seals deteriorate and filters become less effective.

A lot of the original components are starting to show wear and tear. For example, over on the Russian side of the space station, there’s an air leak in the Zvezda module that’s just getting worse and they haven’t been able to fix it. This air leak represents a significant engineering challenge, as it affects not just the immediate safety of the crew but also the long-term sustainability of station operations.

The structural challenges extend beyond individual components. The station’s large size creates significant moment arms that stress the connecting joints. As materials age, these stresses can lead to fatigue failures that are difficult to predict and even more difficult to repair in space.

From a systems engineering perspective, these aging issues create cascading effects. As one system becomes less reliable, it places additional stress on backup systems. This reduces overall system redundancy and increases the risk of catastrophic failure.

Risk Assessment: Safety in the Most Dangerous Phase

NASA’s Aerospace Safety Advisory Panel (ASAP) is worried about the aging International Space Station, saying it is in its riskiest period with the cause of air leaks in the Russian segment still not understood. This assessment reflects the reality that the ISS has entered what many consider its most dangerous operational phase.

The risk factors are multifaceted and interconnected:

Structural Risks: Aging materials and components increase the likelihood of catastrophic failures. The ongoing air leaks in the Russian segment represent a known issue that could worsen without warning.

System Obsolescence: Many ISS systems use technology that is decades old. While proven and reliable, these systems become increasingly difficult to maintain as components become obsolete and expertise retires.

Supply Chain Vulnerabilities: The specialized nature of ISS components means that critical spare parts may not be readily available. Manufacturing replacements for obsolete components can take years.

Crew Safety: As systems become less reliable, the risk to crew safety increases. Emergency procedures must be constantly updated to address new failure modes.

The risk assessment is complicated by the international nature of the partnership. Different space agencies may have different risk tolerances and assessment methodologies. Achieving consensus on safety decisions becomes increasingly challenging as political and technical considerations diverge.

Future Timeline: The Deorbit Decision

The ISS faces a critical decision point regarding its future operations. NASA is crashing the ISS into the ocean at the end of 2030. The agency is collaborating with private companies to build its replacement. However, this timeline isn’t set in stone, and various factors could influence the final decision.

Elon Musk has made it clear; deorbit the International Space Station (ISS) in two years and focus on Mars. This would be before both Russia (2028) and the rest of the ISS partners (2030) plan to end their missions. This perspective reflects concerns about the station’s structural integrity and the opportunity cost of continuing operations.

A NASA official opened the door to keeping the International Space Station in operation beyond 2030 if commercial space stations are not yet ready. This pragmatic approach recognizes that the ISS serves critical functions that must be maintained even if the station itself is aging.

The deorbit decision involves complex engineering challenges. The station’s large size means that controlled deorbit requires careful planning to ensure debris falls into uninhabited areas. Point Nemo, an uninhabited part of the South Pacific ocean, is sometimes called the “spacecraft cemetery.” This location has been identified as the likely target for ISS deorbit.

Commercial Replacement: The Next Generation

The transition from the ISS to commercial space stations represents a fundamental shift in how humanity approaches space-based research. Rather than government-owned and operated facilities, the next generation of space stations will be commercially owned and operated, with government agencies as customers.

This transition creates both opportunities and challenges. Commercial operators can potentially reduce costs and increase innovation through competition. However, they must also maintain the safety and reliability standards established by the ISS program.

Several companies are developing commercial space stations, each with different approaches and capabilities. Some focus on manufacturing and research, while others emphasize space tourism. The diversity of approaches could lead to specialized stations optimized for specific functions.

The engineering challenges of commercial space stations are significant. Companies must develop systems that are both cost-effective and highly reliable. They must also establish supply chains and maintenance procedures that don’t rely on government infrastructure.

Insert image of concept art showing commercial space stations

Lessons Learned: Systems Engineering Insights

The ISS program has generated invaluable lessons for future space systems engineering projects. These insights extend far beyond space applications and have relevance for any complex, safety-critical system.

International Cooperation: The ISS demonstrates that complex engineering projects can succeed even when developed by multiple organizations with different cultures and approaches. However, success requires careful attention to interfaces, standards, and communication protocols.

Modular Design: The modular approach enabled the ISS to be assembled incrementally and upgraded throughout its operational life. This flexibility has been crucial to the station’s longevity and scientific productivity.

Redundancy vs. Complexity: The ISS shows the importance of redundancy in safety-critical systems. However, redundancy also increases complexity, which can introduce new failure modes. The optimal balance depends on the specific system and its operational environment.

Maintenance in Hostile Environments: The ISS experience demonstrates the importance of designing systems for maintenance in challenging environments. This includes not just the systems themselves but also the tools and procedures needed to maintain them.

Risk Management: The ISS program illustrates the challenges of managing risk in complex systems with long operational lives. Risk profiles change over time as systems age and new threats emerge.

Technology Transfer: Earth Benefits from Space Engineering

The engineering solutions developed for the ISS have found applications in numerous Earth-based industries. These technology transfers demonstrate the broader value of space systems engineering beyond the immediate scientific objectives.

Materials Science: Advanced alloys and composites developed for space applications have found uses in aerospace, automotive, and construction industries. The unique properties of space-manufactured materials often cannot be replicated on Earth.

Life Support Systems: Technologies developed for the ISS have applications in remote terrestrial environments, from Antarctic research stations to submarine operations. The closed-loop life support systems are particularly valuable for sustainable living technologies.

Remote Operations: The procedures and technologies developed for operating the ISS remotely have applications in offshore oil platforms, mining operations, and other remote industrial facilities.

Quality Control: The extreme reliability requirements of space systems have led to advanced quality control methodologies that benefit high-reliability Earth-based industries.

Economic Impact: The Value of Space-Based Research

The ISS program represents a significant investment in space-based research capabilities. While the exact cost varies depending on accounting methods, the program has cost over $100 billion since its inception. This investment has generated substantial returns through scientific discoveries and technological innovations.

The economic benefits extend beyond direct technology transfer. The ISS has enabled the development of a commercial space economy, with companies now providing transportation, supplies, and services to the station. This commercial ecosystem reduces costs and increases innovation.

Research conducted on the ISS has led to new pharmaceuticals, materials, and manufacturing processes. While it’s difficult to quantify the exact economic value of these innovations, some studies suggest that the return on investment significantly exceeds the initial cost.

The ISS also serves as a proving ground for space technology that enables future commercial space activities. The experience gained in operating the station has been invaluable for companies developing commercial space stations and other space-based facilities.

Environmental Considerations: Sustainable Space Operations

The ISS program has highlighted the importance of sustainable space operations. As the space environment becomes increasingly crowded, the need for responsible space operations becomes more critical.

The ISS experiences regular encounters with space debris, requiring occasional maneuvers to avoid collisions. These encounters demonstrate the growing problem of space debris and the need for better debris tracking and removal technologies.

The station’s life support systems provide insights into closed-loop environmental systems that have applications for sustainable living on Earth. The ability to recycle air and water with minimal waste is increasingly important as Earth’s population grows.

The planned deorbit of the ISS raises questions about the environmental impact of large space structures. While the controlled deorbit will minimize debris, the precedent sets important standards for future space operations.

Training and Human Factors: Preparing for the Extreme

Operating the ISS requires extensive training in both technical systems and human factors. Astronauts undergo years of training to prepare for the unique challenges of space operations.

The training includes not just technical skills but also psychological preparation for the isolation and stress of space operations. Crew members must be able to work effectively in small teams under high-stress conditions for extended periods.

The ISS experience has provided valuable insights into human factors in extreme environments. These insights have applications in other isolated and confined environments, from Antarctic research stations to long-duration maritime operations.

The multicultural nature of ISS crews has also provided insights into cross-cultural collaboration in high-stress environments. These lessons are valuable for any international engineering project.

Insert image of astronaut training facilities and simulators

Communication Systems: Staying Connected Across the Void

The ISS communication systems represent a critical link between the station and Earth. These systems must operate reliably in the harsh space environment while providing high-bandwidth connections for both operational and scientific data.

The station uses multiple communication systems, including direct radio links to ground stations and relay through tracking and data relay satellites. This redundancy ensures continuous communication even when the station passes out of range of ground stations.

The communication systems have evolved significantly during the station’s operational life. Early systems provided basic voice and low-rate data communications. Current systems support high-definition video, high-speed data transfer, and even internet connectivity for crew members.

The experience with ISS communication systems has been invaluable for developing communication systems for future deep space missions. The Moon and Mars missions will require even more sophisticated communication systems to maintain contact with Earth.

Scientific Legacy: Advancing Human Knowledge

The scientific achievements of the ISS program extend far beyond the immediate research conducted on the station. The unique microgravity environment has enabled discoveries that would have been impossible on Earth.

Protein crystallization experiments on the ISS have led to better understanding of protein structure, which has applications in drug development. Several medications currently in clinical trials are based on research conducted on the ISS.

Materials science research has led to the development of new alloys and composites with properties that cannot be achieved on Earth. These materials have applications in aerospace, automotive, and construction industries.

Biological research on the ISS has provided insights into fundamental life processes and how organisms adapt to extreme environments. This research has implications for both space exploration and Earth-based medical treatments.

The ISS has also served as a testbed for space technology that will enable future exploration missions. From life support systems to materials handling, the station has proven concepts that will be essential for Moon and Mars missions.

Conclusion: Engineering’s Greatest Achievement Faces Tomorrow

The International Space Station stands as humanity’s greatest engineering achievement in space, a testament to what’s possible when brilliant minds collaborate across borders and disciplines. As we’ve explored throughout this analysis, the ISS represents far more than a research facility; it’s a proving ground for the technologies, procedures, and international cooperation frameworks that will enable humanity’s next steps into the cosmos.

From a systems engineering perspective, the ISS offers invaluable lessons about managing complexity, ensuring reliability, and maintaining safety in the most challenging environments. The station’s modular design philosophy, international partnership model, and adaptive maintenance strategies provide blueprints for future space systems.

However, the ISS also faces critical challenges as it enters its most dangerous operational phase. The aging infrastructure, persistent air leaks, and increasing maintenance requirements create a complex risk management scenario that will influence space policy for years to come.

The transition to commercial space stations represents both an opportunity and a challenge. While commercial operators may reduce costs and increase innovation, they must also maintain the safety and reliability standards established by the ISS program. The success of this transition will determine whether the lessons learned from the ISS can be effectively applied to future space operations.

As we look toward the future, the ISS legacy extends far beyond its scientific achievements. The station has demonstrated that complex engineering projects can succeed through international cooperation, provided there’s careful attention to interfaces, standards, and communication protocols. These lessons will be essential as humanity embarks on even more ambitious projects, from lunar bases to Mars colonies.

The ISS has also proven that sustainable space operations are possible, though they require constant vigilance and adaptation. The station’s closed-loop life support systems, debris avoidance procedures, and controlled deorbit planning set important precedents for responsible space operations.

For systems engineers, the ISS program offers a masterclass in managing complexity, uncertainty, and risk over extended time periods. The station’s operational history demonstrates both the power and limitations of redundancy, the importance of maintainability in hostile environments, and the challenges of managing aging infrastructure.

As we prepare for the eventual deorbit of the ISS, we must ensure that the knowledge and expertise gained from this remarkable program aren’t lost. The engineers who designed, built, and operated the ISS have created a legacy that will influence space exploration for generations to come.

The International Space Station may be approaching the end of its operational life, but its impact on human knowledge, international cooperation, and space systems engineering will endure. In the words of those who have dedicated their careers to this remarkable achievement, the ISS isn’t just a space station, it’s a stepping stone to the stars.

What are your thoughts on the ISS transition to commercial space stations? How do you think the lessons learned from this engineering marvel will influence future space projects? Share your insights in the comments below, and let’s continue the conversation about humanity’s next chapter in space exploration.

For more insights into space systems engineering and the challenges of operating complex systems in extreme environments, consider exploring the latest research in space technology development and international space policy. The future of space exploration depends on the lessons we learn today.