Orion Spacecraft: Engineering America’s Next-Generation Deep Space Vehicle

Picture this: you’re standing at Kennedy Space Center, watching a 322-foot rocket pierce the Florida sky. But this isn’t just another launch, you’re witnessing the rebirth of American deep space exploration. The Orion Multi-Purpose Crew Vehicle (Orion MPCV) represents more than NASA’s latest spacecraft; it’s a testament to systems engineering excellence that’s been decades in the making.

As someone who’s spent years in the trenches of space systems development, I can tell you that Orion isn’t just evolution, it’s revolution wrapped in familiar packaging. While its conical shape might remind you of Apollo, the engineering underneath tells a completely different story.

This mission will carry the next astronauts to the moon: https://www.space.com/space-exploration/artemis/nasa-just-got-the-orion-spacecraft-that-will-fly-astronauts-around-the-moon-on-artemis-2-in-2026

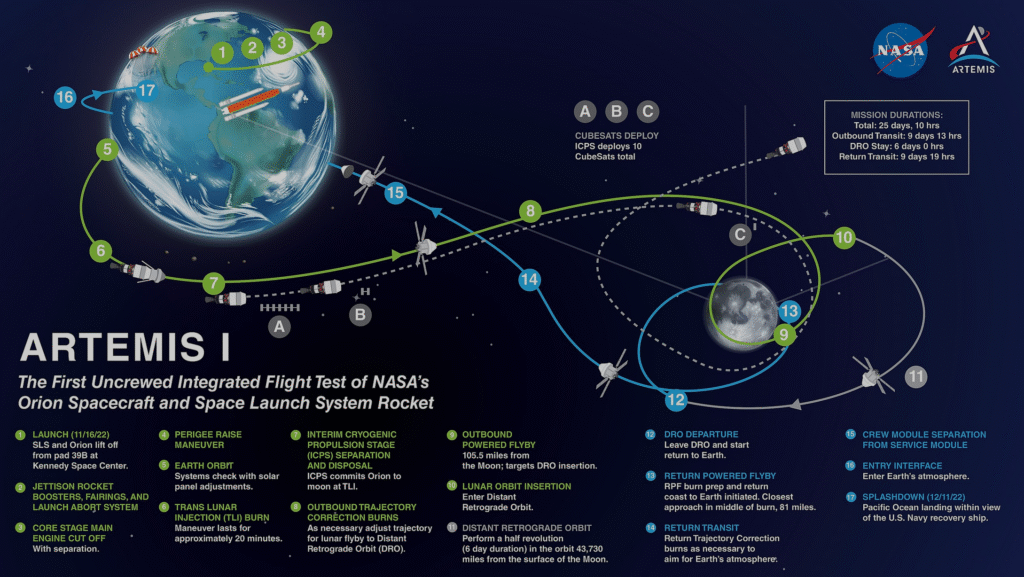

Artemis I Mission – Courtesy of NASA

What Makes Orion Different: Beyond the Basics

The Orion Spacecraft: A Systems Engineer’s Dream

Let’s cut to the chase. When people ask “What is the Orion spacecraft?” they’re really asking about one of the most complex human-rated vehicles ever built. The Orion MPCV is NASA’s flagship deep space exploration vehicle, designed to carry astronauts farther from Earth than any spacecraft since Apollo.

But here’s where it gets interesting from an engineering perspective. Unlike Apollo, which was essentially a sprint to the Moon, Orion was designed for the marathon. We’re talking about missions lasting up to 21 days in deep space, with the capability to support four astronauts in environments that would make Apollo engineers break out in cold sweats.

The spacecraft consists of three primary modules:

- Crew Module (CM): The pressurized living space

- Service Module (SM): The European-built powerhouse

- Launch Abort System (LAS): The ultimate insurance policy

See about the creation of Orion here: https://www.lockheedmartin.com/en-us/products/orion.html

Engineering the Impossible: Technical Specifications That Matter

Here’s where my engineering background kicks in. The crew module is the only part of the spacecraft that returns to Earth after each mission and is a 57.5° frustum shape with a blunt spherical aft end, 5.02 meters (16 ft 6 in) in diameter and 3.3 meters (10 ft 10 in) in length, with a mass of about 8.5 metric tons (19,000 lb).

Those numbers aren’t arbitrary. That specific geometry represents thousands of hours of computational fluid dynamics analysis, thermal modeling, and structural optimization. The 57.5° frustum shape provides optimal aerodynamic performance during atmospheric entry while maximizing internal volume, a classic engineering trade-off.

| Component | Specifications | Engineering Significance |

|---|---|---|

| Crew Module | 5.02m diameter, 3.3m length | 50% larger than Apollo CM |

| Service Module | 4.0m diameter, 4.0m length | Houses 33 engines total |

| Solar Arrays | 4 wings, 7.375m each | Provides 11.1 kW power |

| Mission Duration | Up to 21 days | 3x longer than Apollo |

The European Connection: Why International Partnerships Matter

One of the most brilliant engineering decisions NASA made was partnering with the European Space Agency (ESA) for the service module. ESA has designed and is overseeing the development of Orion’s service module, the part of the spacecraft that supplies air, electricity and propulsion.

This wasn’t just about cost-sharing, it was about leveraging the best engineering talent globally. The European Service Module brings proven ATV (Automated Transfer Vehicle) technology to Orion, including propulsion systems that have already demonstrated their reliability in space.

From a systems engineering perspective, this partnership creates interesting challenges. You’re integrating systems developed under different standards, testing protocols, and quality assurance processes. Yet it works because both organizations understand that space doesn’t care about your nationality, only your engineering competence.

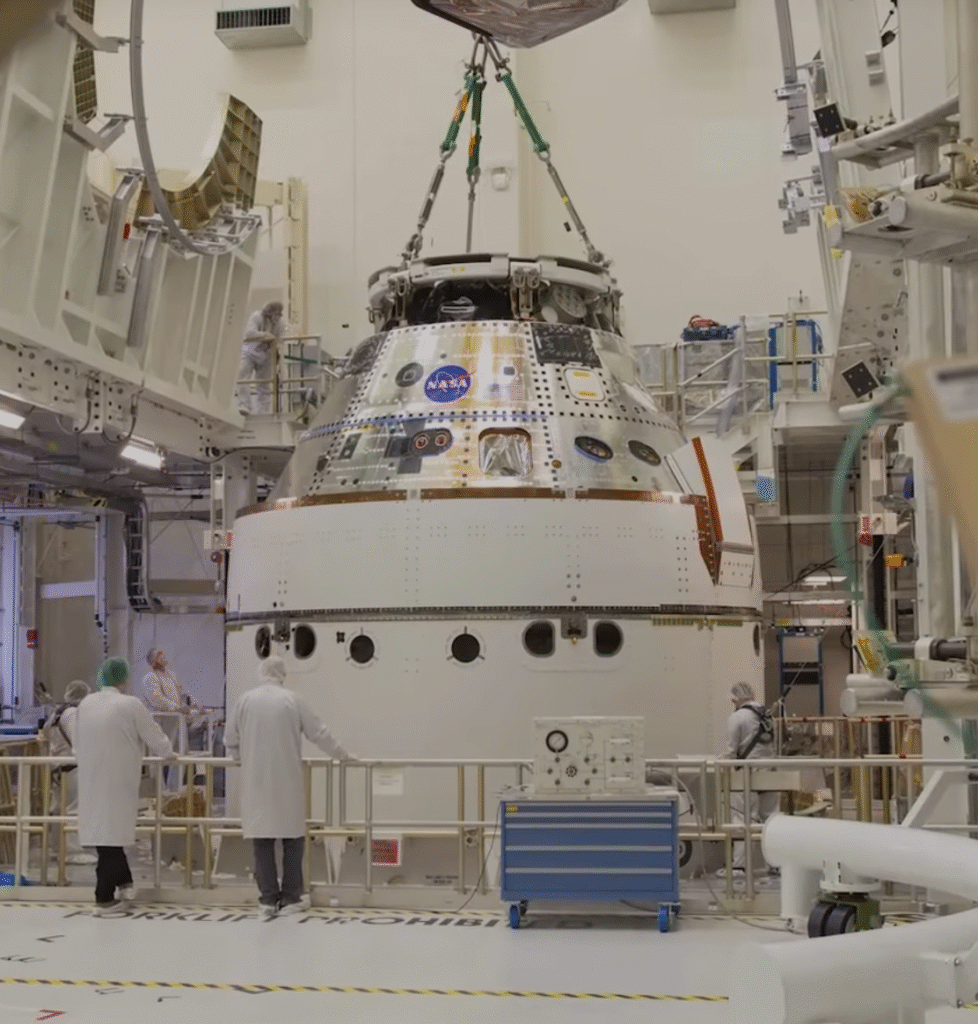

Manufacturing Excellence: Who Builds the Future

Lockheed Martin serves as the prime contractor for Orion, but the reality is more nuanced. With the completion of assembly and testing, Orion has been officially transferred to NASA’s Exploration Ground Systems (EGS) team, marking a significant step toward launching a crew of four astronauts on a 10-day journey to the Moon and back to Earth.

The manufacturing process represents a masterclass in modern aerospace production. Unlike the Apollo era’s essentially hand-built spacecraft, Orion utilizes advanced manufacturing techniques including:

- Friction stir welding for the crew module structure

- 3D printing for complex internal components

- Automated fiber placement for composite structures

- Digital twin technology for manufacturing verification

Orion manufacturing for Artemis II: Courtesy of Lockheed Martin

The Artemis Program: Context and Mission Architecture

Understanding Orion’s Role in Deep Space Exploration

The Artemis program isn’t just about returning to the Moon, it’s about establishing a sustainable presence beyond Earth orbit. Orion serves as the critical transportation node in this architecture, but its role extends far beyond simple crew transport.

Think of Orion as the “pickup truck” of deep space exploration. Their 10-day journey will include flying 4,600 miles beyond the Moon and back to Earth. This trajectory isn’t just about getting there, it’s about proving the systems work in the harsh environment of deep space.

The mission profile for Artemis II demonstrates the spacecraft’s capabilities:

- Launch on SLS: Maximum acceleration and vibration exposure

- Trans-lunar injection: Long-duration coast phase

- Lunar flyby: High-radiation environment

- Free return trajectory: Minimal fuel consumption

- High-speed reentry: 11 km/s velocity

How Many Astronauts Can Orion Carry?

The four-person crew capacity isn’t arbitrary. It represents an optimal balance between mission capability and life support requirements. More crew members mean more consumables, larger environmental control systems, and increased complexity. Four astronauts provide operational flexibility while maintaining system reliability.

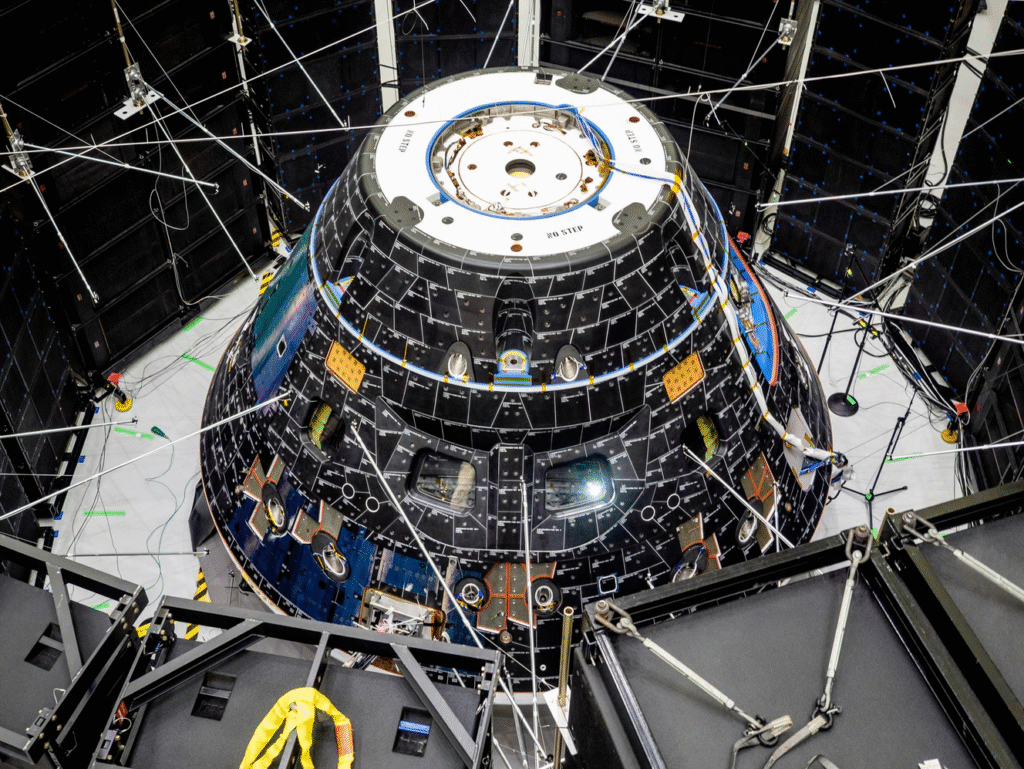

Life Support and Mission Duration: Engineering for Survival

The 21-Day Challenge

When engineers say Orion can support a crew for 21 days, that’s not just about oxygen and water. We’re talking about a complete closed-loop life support system that manages:

- Atmosphere revitalization: CO2 scrubbing and oxygen generation

- Water recovery: Humidity condensate and waste water processing

- Waste management: Solid and liquid waste containment

- Temperature control: Thermal regulation across varying environments

- Fire suppression: Automated detection and suppression systems

The engineering challenge becomes clear when you consider that every system must function flawlessly in zero gravity, high radiation, and extreme temperature variations. There’s no calling for help when you’re three days from Earth.

Artemis I crew module

Read about the life support of the Orion spacecraft here: https://www.nasa.gov/reference/spacecraft-components/

Safety First: The Launch Abort System

Engineering the Ultimate Insurance Policy

The Launch Abort System (LAS) represents one of the most sophisticated safety systems ever developed for human spaceflight. Unlike the Apollo escape tower, which was essentially a solid rocket motor, Orion’s LAS is a precisely controlled system capable of executing different abort modes depending on the flight phase.

The system consists of three solid rocket motors:

- Abort Motor: Provides primary thrust for escape

- Attitude Control Motor: Maintains proper orientation

- Jettison Motor: Separates the LAS post-abort

What makes this system remarkable from an engineering perspective is its ability to execute a successful abort throughout the entire launch profile, including scenarios that would have been impossible for Apollo-era systems.

Technical Deep Dive: Systems That Make It Work

Propulsion: The European Service Module Advantage

The service module has 33 engines, including its large main engine that is used to provide high-power, deep space maneuvers. This isn’t just about redundancy, it’s about mission flexibility.

The propulsion system includes:

- 1 main engine: 33.4 kN thrust (AJ10-190 derivative)

- 8 auxiliary engines: 490 N thrust each

- 24 reaction control engines: 220 N thrust each

This configuration provides multiple levels of redundancy while enabling precise trajectory control. The main engine handles major maneuvers, while the auxiliary engines provide backup capability and fine adjustments.

Power Generation: Solar Array Innovation

Electrical power (120 V) for Orion provided by four wings represents a significant advancement over Apollo’s fuel cell technology. The solar arrays are designed to operate effectively throughout the mission profile, including:

- Near-Earth operations: Standard solar flux

- Deep space cruise: Reduced solar intensity

- Lunar vicinity: Varying solar angles

- Eclipse operations: Battery backup power

The arrays use advanced triple-junction gallium arsenide cells, providing higher efficiency and radiation tolerance than previous generations of space solar technology.

How Orion Differs from Apollo: A Technical Comparison

Beyond Nostalgia: Real Engineering Differences

The visual similarities between Orion and Apollo are superficial. From a systems engineering perspective, they’re completely different vehicles:

| System | Apollo | Orion | Engineering Impact |

|---|---|---|---|

| Crew Capacity | 3 astronauts | 4 astronauts | 33% increase in life support |

| Mission Duration | 12 days max | 21 days max | 75% longer consumables |

| Propulsion | Hypergolic | Hypergolic + ESM | Improved efficiency |

| Power | Fuel cells | Solar arrays | Unlimited duration |

| Computers | AGC | Modern processors | 1000x processing power |

| Heat Shield | Honeycomb | AVCOAT | Improved thermal protection |

The most significant difference is mission flexibility. Apollo was designed for a single mission profile, while Orion can support multiple mission architectures using the same basic vehicle.

Deep Space Communications: Staying Connected

Engineering Solutions for the Communication Challenge

Where Orion is going, there are no GPS or terrestrial communication systems. The spacecraft must maintain contact with Earth across distances that make traditional communication systems inadequate.

Orion’s communication system includes:

- Deep Space Network compatibility: High-gain antennas for long-range communication

- Optical communication experiments: Future high-bandwidth capability

- Emergency beacon systems: Backup communication for contingencies

- Inertial navigation: GPS-independent positioning

The engineering challenge is maintaining reliable communication while conserving power and antenna pointing accuracy across varying spacecraft attitudes and distances.

Radiation Protection: Engineering for the Hostile Environment

The Invisible Enemy

Space radiation represents one of the most significant challenges for deep space missions. Unlike astronauts on the International Space Station, who enjoy protection from Earth’s magnetosphere, Orion crews face the full fury of cosmic radiation and solar particle events.

The spacecraft’s radiation protection strategy includes:

- Structural shielding: Optimized material placement

- Storm shelter: Designated crew protection area

- Dosimetry systems: Real-time radiation monitoring

- Trajectory planning: Avoiding high-radiation zones

The engineering approach balances mass constraints with crew safety, utilizing computational modeling to optimize shielding effectiveness while maintaining structural integrity.

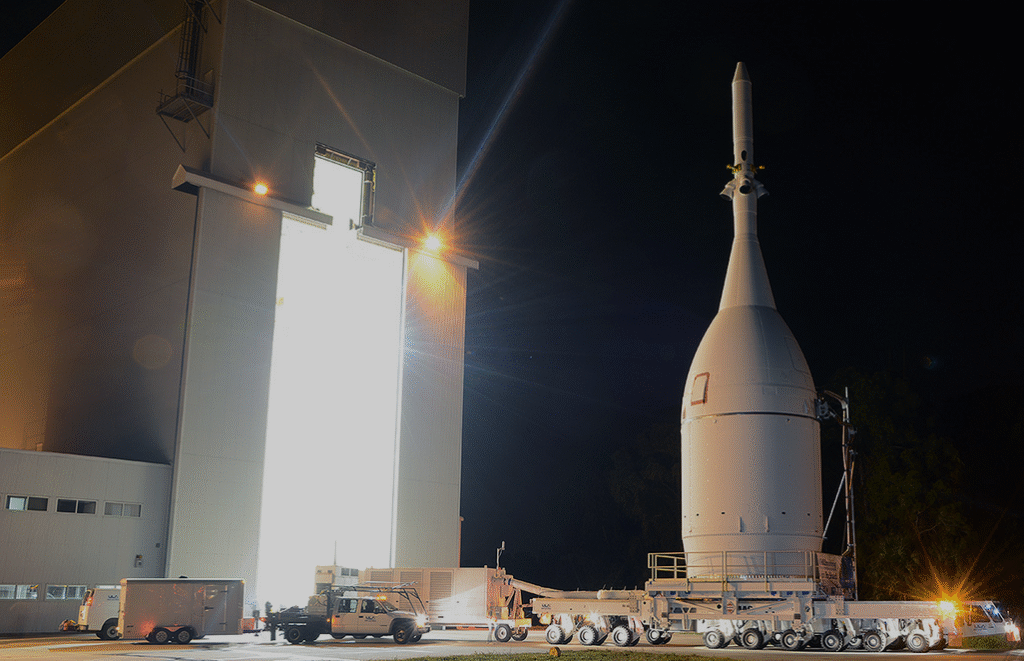

The Space Launch System Integration

Engineering the Ultimate Ride

Orion doesn’t exist in isolation, it’s part of an integrated launch system that includes the most powerful rocket NASA has ever built. The Space Launch System (SLS) provides the energy needed to send Orion on deep space missions, but the integration challenges are substantial.

The engineering considerations include:

- Structural loads: Maximum dynamic pressure and acceleration

- Acoustic environment: Sound suppression and vibration isolation

- Thermal protection: Launch heating and cooling cycles

- Abort scenarios: Safe crew escape throughout launch profile

The Orion-SLS integration represents one of the most complex engineering challenges in aerospace, requiring precise coordination between multiple contractors and agencies.

Current Status: Where We Stand Today

Artemis II: The Next Major Milestone

A stacking of Orion atop SLS in fall could allow a rollout of the Artemis II SLS and Mobile Launcher 1 to the launch complex around the very end of 2025 or the start of 2026. This timeline reflects the reality of complex systems engineering, every component must be thoroughly tested and verified before human lives are at stake.

The current status includes:

- Artemis I: Successfully completed (December 2022)

- Artemis II: Crew assigned, vehicle in final processing

- Artemis III: NASA officially delayed Artemis III to no earlier than 2027

These timelines reflect the engineering reality that complex systems require extensive testing and validation before they’re ready for human spaceflight.

Future Missions: Beyond the Moon

Engineering for Multiple Destinations

While Orion is currently focused on lunar missions, its design enables missions to multiple destinations:

- Near-Earth asteroids: Extended duration missions

- Mars vicinity: Conjunction-class trajectories

- Deep space observatories: Lagrange point operations

- Interplanetary missions: Advanced propulsion integration

The spacecraft’s modular design allows for mission-specific modifications while maintaining core systems compatibility.

Docking and Rendezvous: Precision Engineering

The Art of Orbital Mechanics

Orion’s docking capabilities represent a significant advancement over Apollo-era systems. The spacecraft can autonomously dock with:

- Lunar Gateway: NASA’s planned lunar space station

- Commercial vehicles: SpaceX Starship and other landers

- International partners: Future cooperative missions

The docking system uses advanced sensors and automated control algorithms to execute precise rendezvous maneuvers, even in the challenging environment around the Moon.

Reentry and Recovery: Coming Home Safely

Engineering for the Most Dangerous Phase

Orion’s reentry profile is significantly more challenging than Apollo’s. Orion’s 970 outer tiles are made of the same material as the tiles that protected the shuttle. However, the thermal protection system is optimized for the higher velocities associated with deep space returns.

The reentry system includes:

- AVCOAT heat shield: Ablative thermal protection

- Backshell protection: Spacecraft structure shielding

- Parachute system: Three-stage descent profile

- Impact attenuation: Crew protection during splashdown

The engineering challenge is managing the 11 km/s reentry velocity while maintaining crew safety and spacecraft integrity.

Program Challenges and Engineering Solutions

Budget Constraints and Technical Realities

The second Trump administration released its fiscal year 2026 budget proposal, which proposed canceling the SLS and Orion spacecraft after Artemis III due to the former’s cost of $4 billion per launch. This political reality highlights the ongoing challenge of balancing engineering excellence with fiscal responsibility.

The engineering community’s response involves:

- Cost reduction initiatives: Manufacturing efficiency improvements

- Reusability studies: Extending vehicle operational life

- Commercial partnerships: Leveraging private sector innovation

- International cooperation: Sharing development costs

Interior Design: Human Factors Engineering

Creating a Livable Workspace

The Orion spacecraft interior represents a masterclass in human factors engineering. Unlike Apollo’s cramped quarters, Orion provides:

- Ergonomic crew stations: Optimized for long-duration missions

- Modular storage: Efficient use of limited volume

- Exercise equipment: Maintaining crew health

- Private crew quarters: Psychological well-being considerations

The interior design balances functionality with the psychological needs of astronauts on extended missions far from Earth.

Lessons Learned: Engineering Insights

What We’ve Learned from Artemis I

The uncrewed Artemis I mission provided invaluable engineering data:

- Thermal performance: Heat shield effectiveness validation

- Structural integrity: Launch and reentry loads confirmation

- Systems performance: Life support and power system validation

- Communication systems: Deep space network compatibility

These lessons inform ongoing engineering improvements and future mission planning.

The Engineering Legacy

Building on Apollo, Reaching for Mars

Orion represents more than just the next generation of spacecraft, it’s a testament to the evolution of systems engineering. The lessons learned from Apollo, combined with modern technology and international cooperation, have created a vehicle capable of supporting humanity’s expansion into the solar system.

The engineering challenges overcome in Orion’s development, from radiation protection to deep space communication, provide the foundation for even more ambitious missions. Whether it’s establishing a permanent lunar presence or eventually reaching Mars, Orion’s engineering legacy will enable humanity’s next giant leap.

As we stand on the threshold of a new era in space exploration, Orion serves as both a bridge to our past achievements and a pathway to our future among the stars. The engineering excellence embodied in this spacecraft represents the best of human ingenuity, international cooperation, and the relentless pursuit of knowledge that drives us to explore the cosmos.

The next time you see that familiar conical shape lifting off from Kennedy Space Center, remember that you’re witnessing more than a launch, you’re seeing the culmination of decades of engineering evolution, carrying humanity’s dreams to destinations that were once the realm of science fiction.

Orion on the Launch Pad

What aspects of Orion’s engineering design intrigue you most? Are there specific systems or challenges you’d like to explore further? Share your thoughts and questions about this remarkable spacecraft that’s opening new frontiers in human space exploration.

About the Author: With over a decade of experience in space systems engineering, including work supporting critical defense applications, I’ve witnessed firsthand the evolution of spacecraft design from concept to reality. Orion represents the pinnacle of what’s possible when engineering excellence meets human ambition.