Introduction: When Dreams Meet Engineering Reality – James Webb Telescope

Picture this: You’re designing a telescope that needs to be 100 times more powerful than Hubble, operate in the vacuum of space at temperatures colder than Pluto, and unfold itself with the precision of a Swiss watchmaker, all while being a million miles away from Earth. Sounds impossible? Welcome to the James Webb Space Telescope (JWST), humanity’s most ambitious space engineering project that’s currently rewriting the textbooks on what’s possible in the cosmos.

The James Webb Space Telescope isn’t just another piece of space hardware, it’s a testament to what happens when cutting-edge engineering meets audacious scientific ambition. Since its launch, this $10 billion marvel has been delivering discoveries that are literally jaw-dropping, from discovering its first exoplanet TWA 7b, which is also the lightest exoplanet ever to be directly imaged to revealing the intricate structure of distant galaxies with unprecedented clarity.

As someone who’s spent a decade in the space industry, I can tell you that JWST represents the pinnacle of systems engineering achievement. Moreover, it’s not just changing astronomy, it’s revolutionizing how we approach complex space systems design and deployment.

James Webb Telescope Primary Mirror

What Makes the James Webb Space Telescope Special?

The Engineering Foundation

The James Webb Space Telescope is fundamentally different from its predecessors, and understanding these differences is crucial for any systems engineer. Unlike Hubble, which operates in low Earth orbit and observes primarily in visible light, JWST is positioned at the second Lagrange point (L2) and specializes in infrared astronomy.

This strategic positioning at L2, approximately 1.5 million kilometers from Earth, provides several engineering advantages. First, it maintains a stable thermal environment, crucial for infrared observations. Second, it allows continuous observation without Earth’s shadow interference. However, it also presents unique challenges, there’s no possibility of servicing missions, meaning everything must work perfectly from day one.

The telescope’s primary mirror spans 6.5 meters in diameter, composed of 18 hexagonal segments made of beryllium and coated with a microscopically thin layer of gold. Each segment can be individually adjusted with nanometer precision, essentially creating a perfect mirror through active control systems.

Revolutionary Technology Integration

What sets JWST apart isn’t just its size, it’s the integration of multiple breakthrough technologies working in harmony. The sunshield, larger than a tennis court when deployed, maintains a temperature differential of over 300 degrees Celsius between its hot and cold sides. This engineering marvel consists of five layers of specialized material, each thinner than human hair yet capable of withstanding the harsh space environment.

The telescope’s four primary science instruments represent the state-of-the-art in space-based detection technology:

- Near Infrared Camera (NIRCam): Primary imager covering 0.6 to 5.0 micrometers

- Near Infrared Spectrograph (NIRSpec): Multi-object spectroscopy capabilities

- Mid-Infrared Instrument (MIRI): Operating at extremely cold temperatures

- Fine Guidance Sensor/Near InfraRed Imager and Slitless Spectrograph (FGS/NIRISS): Providing precision pointing

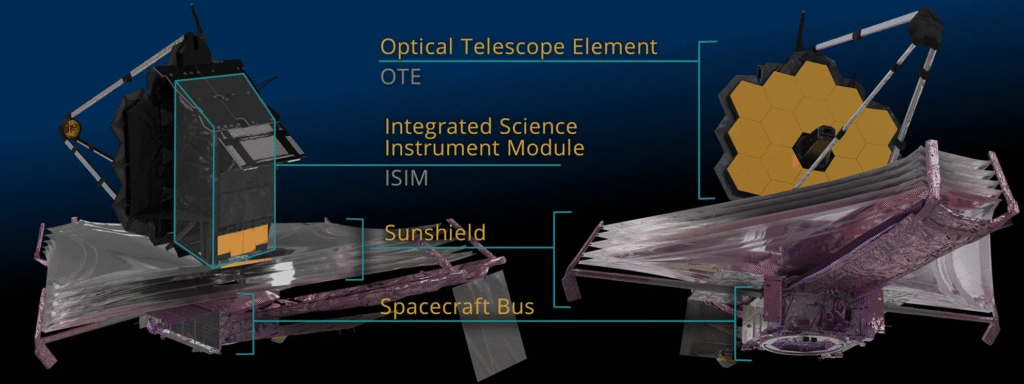

James Webb Bus Components; Credit NASA

Launch and Deployment: A Systems Engineering Masterpiece

The Launch Campaign

The James Webb Telescope launch on December 25, 2021, represented one of the most complex space missions ever attempted. Launched aboard an Ariane 5 rocket from French Guiana, the telescope had to be folded like an intricate origami sculpture to fit within the rocket’s payload fairing.

The launch itself was nearly flawless, with the rocket providing such precise insertion that JWST gained several years of operational life due to reduced fuel consumption for trajectory corrections. This precision demonstrates the critical importance of launch vehicle selection and trajectory optimization in space systems engineering.

The Deployment Sequence

The deployment of JWST over the following six months was nothing short of miraculous from an engineering perspective. The telescope had to execute over 300 single-point-of-failure mechanisms, each one critical to mission success. The deployment sequence included:

- Solar array deployment: Providing immediate power generation

- High-gain antenna deployment: Establishing communication with Earth

- Sunshield deployment: Five-layer thermal protection system

- Secondary mirror deployment: Completing the optical system

- Primary mirror unfolding: 18 segments precisely positioned

Each step required careful coordination between multiple subsystems, demonstrating the importance of robust systems integration and verification processes.

See JWST Timeline of Milestones HERE: https://webbtelescope.org/news/milestones/mission-timeline

Groundbreaking Discoveries: Where Engineering Meets Science

Recent Discoveries in 2025

The James Webb Telescope discoveries continue to astound the scientific community. Recent observations have revealed fine details resembling the knots and whorls of wood grain in interstellar dust and gas, allowing astronomers to map the true 3D structure of the interstellar medium for the first time. Additionally, astronomers have discovered water ice in a band of icy bodies at the edge of a distant star system around the star HD 181327.

These discoveries aren’t just scientifically significant, they demonstrate the telescope’s engineering capabilities operating at the limits of what’s technically possible. The precision required to detect these subtle signatures while operating in the extreme environment of space showcases the robustness of the design.

Exoplanet Research Breakthroughs

The telescope’s exoplanet research capabilities have exceeded all expectations. For the first time ever, the James Webb Space Telescope has discovered an exoplanet by directly imaging it, with the newfound world having a mass roughly similar to Saturn. This capability opens new avenues for atmospheric characterization and potentially habitable world detection.

The engineering challenge of detecting these faint signals requires extraordinary stability and precision. The telescope’s ability to maintain pointing accuracy while rejecting thermal noise demonstrates advanced control systems engineering principles in action.

Galaxy Formation Studies

JWST’s observations of distant galaxies are revealing the universe’s earliest epochs with unprecedented clarity. The telescope can observe galaxies as they existed when the universe was only a few hundred million years old, providing insights into cosmic evolution that were previously theoretical. See about the improvements of James Webb over Hubble here:

https://science.nasa.gov/mission/hubble/observatory/hubble-vs-webb/

| Parameter | James Webb Space Telescope | Hubble Space Telescope |

|---|---|---|

| Primary Mirror Diameter | 6.5 meters | 2.4 meters |

| Wavelength Range | 0.6 – 28.5 micrometers | 0.1 – 2.5 micrometers |

| Operating Temperature | ~50 Kelvin | ~288 Kelvin |

| Location | L2 Lagrange Point | Low Earth Orbit |

| Light Gathering Power | ~6.25x greater | Baseline |

Technical Deep Dive: Engineering the Impossible

Mirror Design and Manufacturing

The James Webb Telescope mirror design represents a paradigm shift in space optics. Traditional space telescopes use monolithic mirrors, but JWST’s segmented approach allows for larger apertures while maintaining launch compatibility. Each beryllium segment weighs approximately 20 kilograms and is polished to within 10 nanometers of perfection.

The gold coating serves multiple purposes beyond aesthetic appeal. Gold’s excellent infrared reflectivity and resistance to oxidation make it ideal for the telescope’s mission requirements. However, applying a uniform 100-nanometer gold layer across 18 individual segments while maintaining optical precision required developing entirely new manufacturing processes.

Sunshield Technology Innovation

The sunshield represents one of JWST’s most innovative engineering achievements. The five-layer design uses advanced materials including Kapton with aluminum and silicon coatings. The engineering challenge involved creating a deployable structure that could unfold reliably in space while maintaining precise layer separation.

Temperature management across the sunshield is critical, the sun-facing side reaches approximately 85°C while the telescope side operates at -233°C. This 300-degree differential is maintained through careful thermal design and material selection, demonstrating advanced thermal engineering principles.

Advanced Control Systems

JWST’s precision pointing and stability requirements pushed control systems engineering to new limits. The telescope must maintain pointing accuracy to within 0.007 arcseconds, equivalent to the width of a human hair viewed from 1.6 kilometers away.

The control system integrates multiple sensors and actuators:

- Star trackers: Providing absolute attitude reference

- Gyroscopes: Measuring angular rates

- Reaction wheels: Momentum storage and attitude control

- Thrusters: Momentum dumping and orbit maintenance

Insert technical diagram of JWST control system architecture

Infrared Capabilities: Seeing the Invisible Universe

Why Infrared Matters

The James Webb Telescope infrared capabilities unlock observations impossible with visible light telescopes. Infrared radiation penetrates cosmic dust that obscures visible light, revealing star formation regions and distant galaxies previously hidden from view.

From an engineering perspective, infrared astronomy presents unique challenges. Thermal noise becomes the dominant limiting factor, requiring extreme cooling and sophisticated signal processing. JWST’s MIRI instrument operates at just 7 Kelvin, colder than the cosmic microwave background radiation.

Thermal Management Systems

Maintaining the required operating temperatures involves multiple engineering systems working in concert. The passive cooling provided by the sunshield brings most instruments to approximately 50 Kelvin, but MIRI requires active cooling through a three-stage cryocooler system.

The cryocooler represents a remarkable engineering achievement, it must operate reliably in space for the entire mission duration while consuming minimal power. The system uses advanced thermodynamic cycles and precision mechanical components to achieve the required cooling performance.

Detector Technology

JWST’s infrared detectors utilize cutting-edge technology to achieve unprecedented sensitivity. The detectors use mercury-cadmium-telluride (HgCdTe) arrays with sophisticated readout electronics. These detectors can register single photons, pushing the limits of quantum detection technology.

The engineering challenge involves not just the detectors themselves but also the associated electronics that must operate at cryogenic temperatures while maintaining extremely low noise levels. This requires careful component selection and circuit design optimized for the space environment.

Comparing Giants: JWST vs Hubble Engineering

Design Philosophy Differences

The engineering approaches of JWST and Hubble reflect different eras of space technology and scientific requirements. Hubble’s design prioritized serviceability and longevity in low Earth orbit, while JWST emphasizes performance and capability at L2.

Hubble’s monolithic design allows for component replacement and upgrades, demonstrated through five successful servicing missions. JWST’s distributed architecture maximizes performance but requires everything to work correctly from deployment, there’s no second chance.

Technological Evolution

The 30-year gap between Hubble’s design and JWST’s development represents a technological revolution. Advances in materials science, control systems, and manufacturing processes enabled JWST’s revolutionary capabilities.

Consider the pointing accuracy requirements: Hubble achieves 0.012 arcseconds, impressive for its era. JWST’s 0.007 arcseconds represents a 40% improvement while operating at twice the distance from Earth with a structure six times larger.

Mission Architecture Trade-offs

The decision to place JWST at L2 versus low Earth orbit involved complex trade-offs. L2 provides thermal stability and continuous observation capability but eliminates servicing options. This architectural decision drove requirements for unprecedented reliability and autonomous operation.

From a systems engineering perspective, this trade-off demonstrates the importance of requirement analysis and risk assessment in mission architecture decisions. The benefits of L2 operation were deemed worth the increased reliability requirements.

Insert comparison infographic showing key differences between JWST and Hubble

Mission Timeline and Operational Phases

Pre-Launch Development

The JWST mission timeline spans over two decades from initial concept to operational capability. The development phase involved extensive testing and verification, including full-scale deployment tests in thermal vacuum chambers.

The engineering challenges during development required innovative solutions. For example, testing the sunshield deployment on Earth required specialized facilities to simulate the space environment while supporting the structure against gravity.

Launch and Commissioning

The six-month commissioning phase following launch demonstrated the robustness of the engineering design. Each deployment step was carefully executed with extensive ground-based monitoring and analysis.

The commissioning process included:

- Optical alignment: Precisely positioning 18 mirror segments

- Instrument calibration: Verifying performance specifications

- System integration: Confirming all subsystems work together

- Science verification: Demonstrating scientific capabilities

Operational Phase

JWST’s operational phase began in July 2022 and continues today. The telescope operates with remarkable efficiency, typically exceeding performance specifications. The operational success demonstrates the effectiveness of the engineering approach and the importance of thorough testing and verification.

The telescope’s operational lifetime is currently estimated at 10-20 years, limited primarily by propellant for station-keeping at L2. The precise launch insertion and efficient operations have extended this estimate well beyond the original minimum requirement.

Public Access and Data Systems

Data Processing Architecture

The James Webb Telescope generates enormous amounts of data, up to 57 gigabytes per day. Managing this data stream requires sophisticated ground-based processing systems and careful bandwidth allocation.

The data processing pipeline involves multiple stages:

- Raw data capture: Direct from telescope telemetry

- Calibration: Applying instrument-specific corrections

- Processing: Converting to science-ready formats

- Archive: Long-term storage and public access

Public Data Access

NASA provides public access to JWST data through the Mikulski Archive for Space Telescopes (MAST). This open-access policy maximizes the scientific return on the mission investment while demonstrating transparency in publicly funded research.

The engineering challenge involves creating user-friendly interfaces while maintaining data integrity and providing appropriate documentation. The system must handle requests from professional astronomers to curious students with varying technical backgrounds.

Real-time Operations

JWST operations require continuous monitoring and occasional adjustments. The Deep Space Network provides communication capability, but the 5-second light-travel time to L2 means real-time control is impossible.

This operational constraint drove requirements for autonomous operation and sophisticated fault detection and recovery systems. The telescope must handle routine operations independently while alerting ground controllers to any anomalies.

Engineering Challenges and Solutions

Deployment Complexity

The deployment of JWST represented one of the most complex space engineering challenges ever attempted. With over 300 single-point-of-failure mechanisms, the deployment sequence required unprecedented reliability.

The engineering solution involved extensive testing, redundancy where possible, and careful failure mode analysis. Each deployment step was thoroughly analyzed and tested, with contingency procedures developed for potential anomalies.

Thermal Management

Maintaining the required temperature differentials across the telescope structure required innovative thermal engineering. The sunshield provides passive cooling, but achieving the precise temperatures needed for optimal performance required active thermal control.

The engineering approach integrated passive and active thermal management systems with sophisticated modeling and control algorithms. The result is a system that maintains temperatures within tight tolerances despite the varying solar exposure and operational conditions.

Pointing and Stability

JWST’s pointing accuracy requirements pushed the limits of space-based control systems. The telescope must maintain precise pointing while rejecting disturbances from solar radiation pressure, thermal variations, and internal mechanisms.

The engineering solution combines multiple control approaches:

- Coarse pointing: Using reaction wheels for large slews

- Fine pointing: Using fine guidance sensors and mirror actuators

- Vibration isolation: Minimizing disturbances from onboard mechanisms

Insert technical diagram showing JWST’s pointing control system

Future Implications for Space Systems Engineering

Lessons Learned

JWST’s success provides valuable lessons for future space systems engineering projects. The importance of thorough testing, conservative design margins, and robust systems integration cannot be overstated.

Key takeaways include:

- Early integration: Testing complete systems rather than individual components

- Failure mode analysis: Comprehensive analysis of potential failure modes

- Operational procedures: Well-defined procedures for normal and contingency operations

- International collaboration: Leveraging global expertise and resources

Technology Advancement

The technologies developed for JWST are finding applications in other space missions. The deployment mechanisms, thermal management systems, and precision control technologies are being adapted for future telescopes and spacecraft.

This technology transfer demonstrates the broader value of ambitious engineering projects beyond their primary mission objectives. The engineering innovations developed for JWST will benefit space exploration for decades to come.

Next-Generation Missions

JWST’s success is enabling even more ambitious future missions. Concepts for extremely large space telescopes, interferometric arrays, and specialized instruments are being developed based on JWST’s technological foundation.

The engineering confidence gained from JWST’s success is encouraging more ambitious mission concepts. Projects that seemed impossible a decade ago are now considered feasible based on the demonstrated capabilities.

Conclusion: Engineering Excellence Meets Scientific Discovery

The James Webb Space Telescope stands as a testament to what’s possible when engineering excellence meets scientific ambition. From its revolutionary mirror design to its unprecedented thermal management systems, JWST represents the pinnacle of space systems engineering achievement.

As we’ve explored, the telescope’s success isn’t just about the spectacular images it produces, it’s about the engineering discipline, innovative solutions, and meticulous attention to detail that made those discoveries possible. The lessons learned from JWST’s development and operation will influence space systems engineering for generations to come.

The telescope continues to exceed expectations, delivering scientific discoveries that are rewriting our understanding of the universe while demonstrating the reliability and capability of advanced space systems. For engineers working on complex systems, JWST provides a masterclass in requirement analysis, systems integration, and operational excellence.

As we look to the future, JWST’s legacy extends beyond its scientific contributions. It has proven that seemingly impossible engineering challenges can be overcome through careful analysis, innovative solutions, and unwavering commitment to excellence. The telescope stands as inspiration for the next generation of space systems engineers who will build upon its technological foundation to explore even greater frontiers.

The James Webb Space Telescope isn’t just observing the universe, it’s showing us what’s possible when engineering dreams become reality. And in a field where the impossible becomes routine, that’s perhaps the most important discovery of all.

See all about the James Webb Telescope at the official site: https://webbtelescope.org/

About the Author: Drawing from a decade of experience in space systems engineering, this analysis examines JWST through the lens of practical engineering challenges and solutions. The telescope’s success demonstrates the critical importance of systems engineering discipline in achieving ambitious space exploration goals.